Solar power is amazing and awesome, but there has to be a place to store the power. It’s a great additional option, but you still need to have consistent and reliable power that is not dependent upon the sun. That’s where batteries come in. The Kadey Krogen 39 had 6 8D AGM batteries (2 for the bowthruster and four in the house bank. The house bank was also used as the engine starting battery. A dead give-away that the batteries are at the end of their life is when the electronics often shut down due to low voltage when starting the engine.

Four batteries needed to be replaced.

We had battery discussions for weeks. Is it a discussion when one party can only listen and ask questions without understanding? I even watched a YouTube video on batteries to assist my comprehension. I am grateful for Anthony who would step in, over long distance, to carry this battery discussion burden for me.

What were the options? -Golf cart wet cells or golf cart AGM? 8D wet cells or 8D AGM?

The considerations, of course, were weight, price, and maintenance. The golf cart options are smaller and weigh less which is a major factor for a do-it-yourselfer like Al. Wet cells require the regular routine maintenance of checking and adding water once or twice each month. AGMs (Absorbent Glass Matt) are maintenance-free. The 8Ds have a deeper cycle which means they are able to hold deeper discharges and have a much longer service life. But…. and this is a big but, they weigh much more (152lbs) than the equivalent two 6-volt lead-acid golf cart batteries (each 56lbs). How’s that? Do I understand the basics of battery options now?

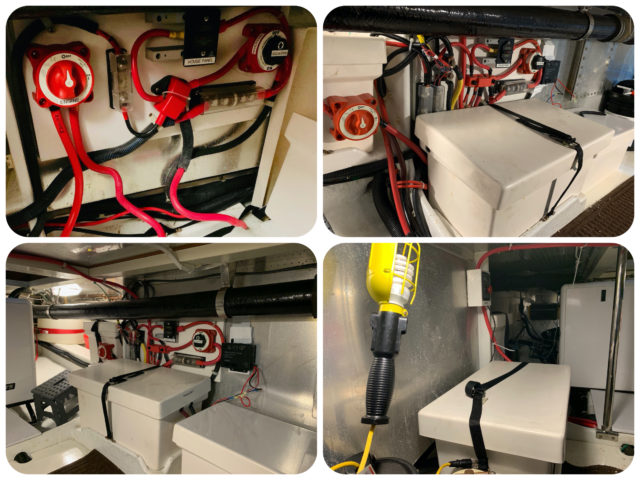

Decision? Get four new 8D AGM batteries or eight 6 volts golf cart batteries, Of the three considerations, the 8D’s weigh more and they cost more, but they are maintenance free and match the remaining batteries which is also an important factor. The boxes were already in place so there would be no need to build or modify those.

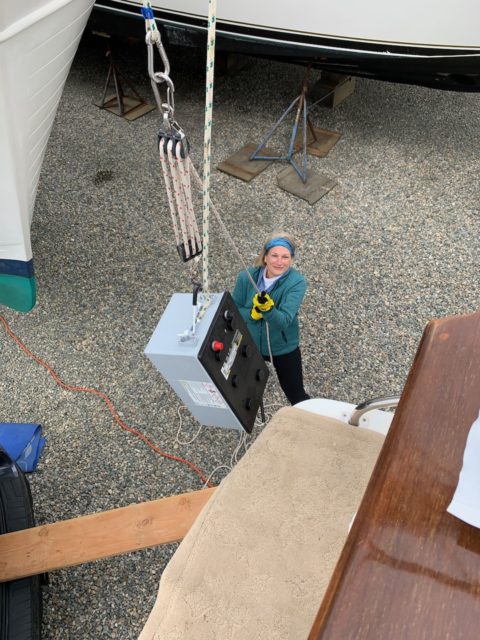

Making the decision was not enough to make it happen. Al had to find the batteries nearby (no shipping of these 152lb each babies) and had to make a plan for getting the batteries into the boat and in their proper functioning locations.

My Dad always called Al “McGyver” because he could find a solution to any mechanical problems. This would be one of Al’s finest McGyver moments. The old batteries had to be removed and Al “McGyver’ed that all alone. No pictures to prove it, though. 🙁 The photos below are all from the installation of the new batteries.

Take note that all of this happened back in April, before my accident. It was also during the covid-19’s shut down so hiring young strong weightlifters was not a viable option. I was happy to help Al in this major endeavor. It also proves that I actually help with some maintenance projects!

OK. Two down, two to go. The next two batteries are for the bowthruster and will reside under the stateroom berth. The car to salon process was repeated again, but these two batteries had to go from the salon all the way forward to the master cabin.

This was the most expensive project of the winter, but a necessary one. No one wants to worry and stress about battery issues while out cruising.

Nicholas Gibbens

Thanks a clean set up in the bow

Anthony W Baker

You two are the BOMB!!!!