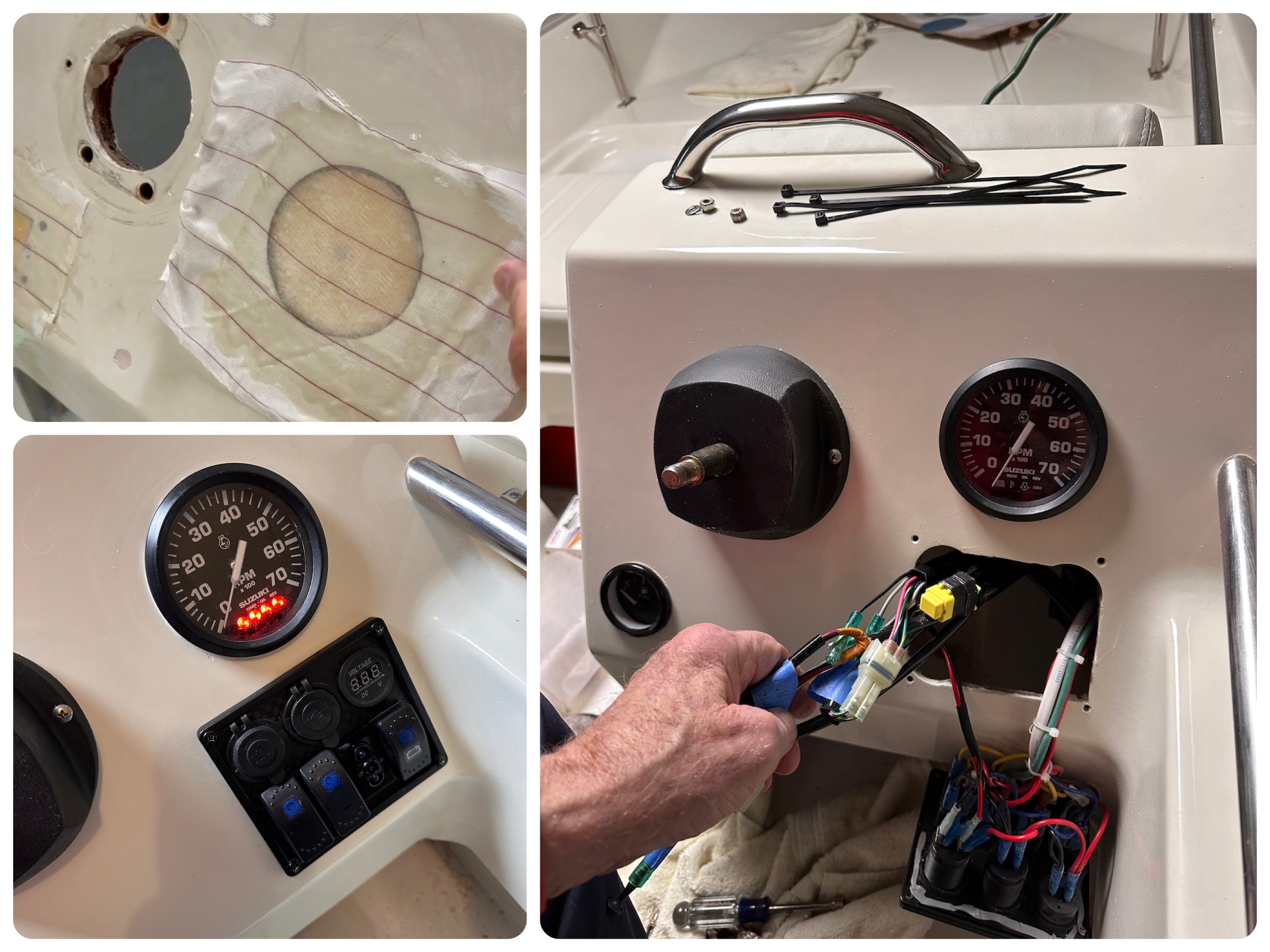

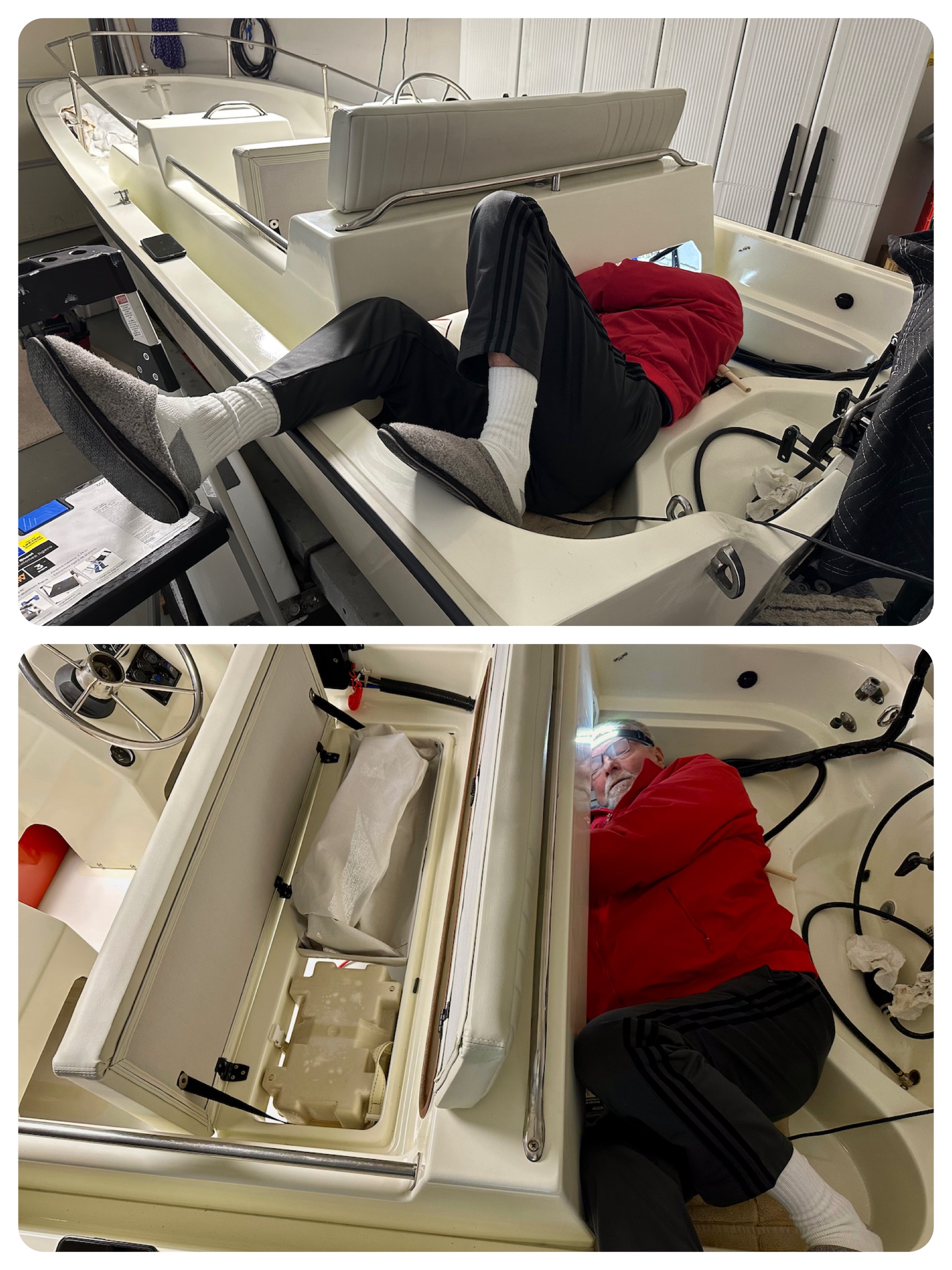

Restoring this old Boston Whaler was more than just fiberglass and gelcoat repairs. There were still other details like cushions, a gas tank, steering controls and gauges, and oh, an engine! None of this discouraged Al. Not one bit.

The cushions….. The whaler had homemade blue-covered fabric over old foam, on top of aging wood for seating. While Al had the top part in the basement, he made new solid wood bases for the future new cushions.

Al researched fabric options and color choices and chose a “griege” (gray-beige) in a sturdy vinyl.

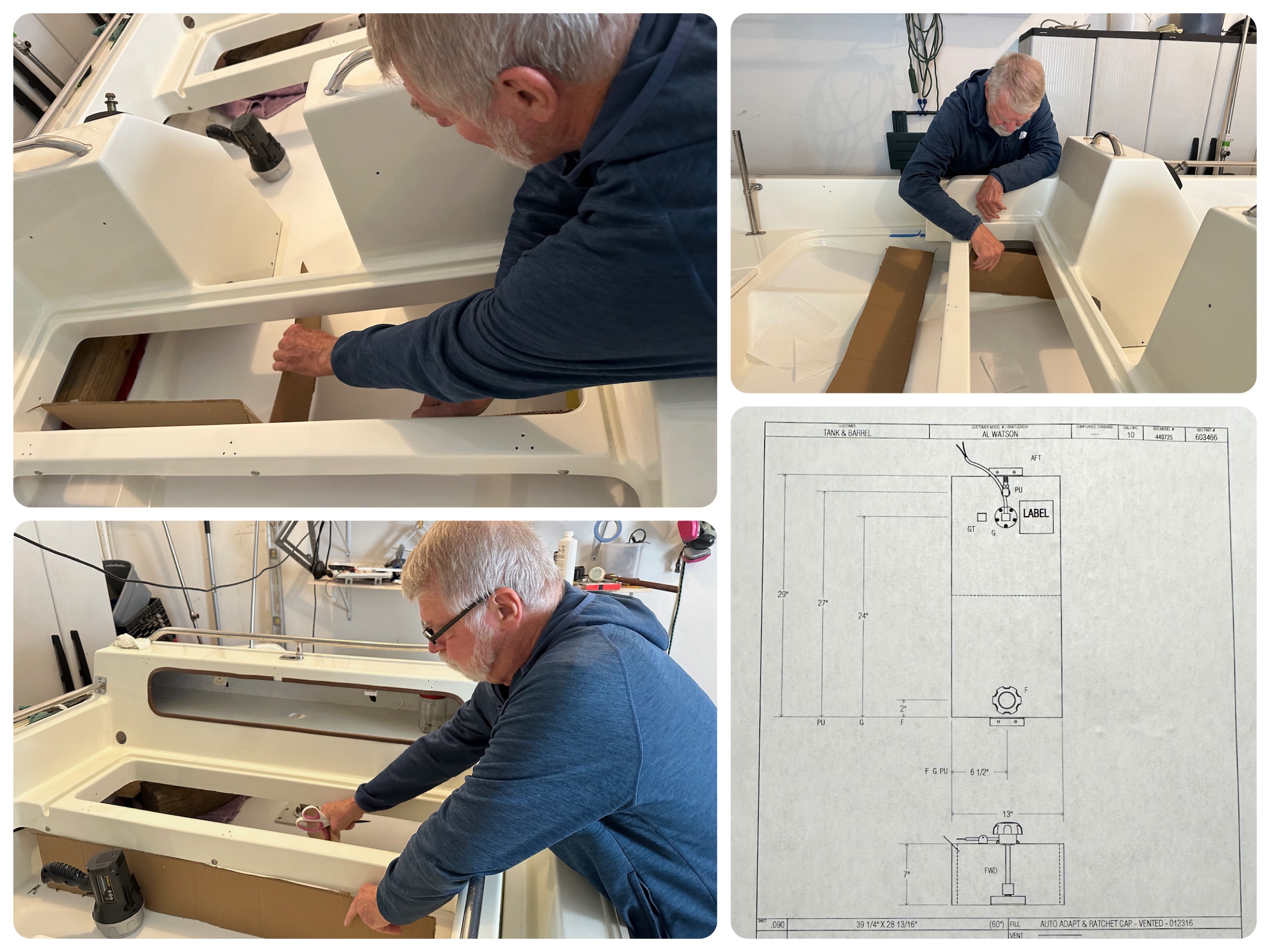

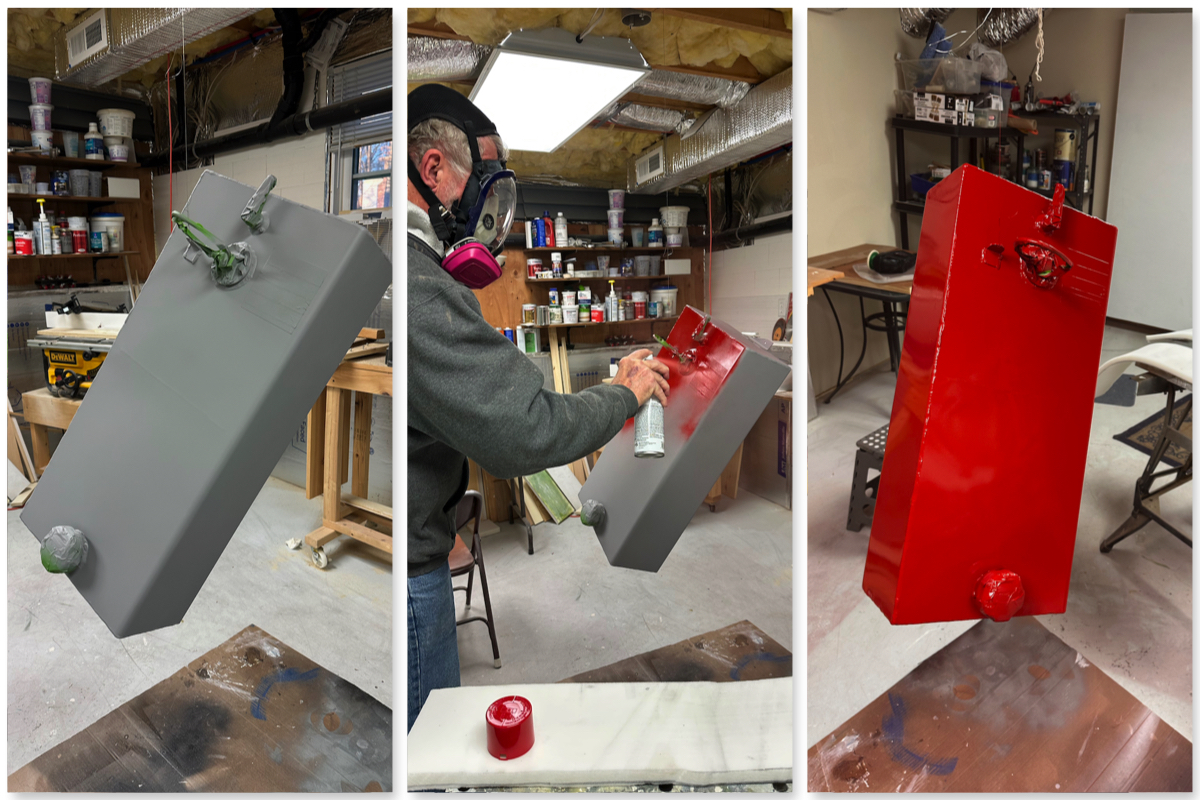

The gas tank…. Boston Whalers from this period generally have plastic gas containers that sit in the back. Al didn’t care for that “look” in his watsonized whaler and that location adds a lot of weight to the back of the boat.

His solution? Search online for gas tanks that could fit under the front seat, relocating that weight forward for more stability. He could not find a ready-made tank that would work so he calculated the dimensions he would need and had a custom tank made to fit.

The engine .… The Boston Whaler was still missing one very, very important component – an engine. As soon as the boat was delivered here in July, Al started searching online for a used engine in the 40-60 hp range. By January, he had not found anything that was reasonably priced and in a good enough condition to have confidence that it would continue to function. There is also lots of debate, online, about what horsepower should be used on this size Whaler. Some owners insist that a 70 or 90 hp is needed. Ha. We are not speed freaks.

We went to the Hartford Boat Show just for a fun day out and to “look” at outboard engines, especially any used ones that a dealer might have. Gales Ferry Marina is a Suzuki dealer and had a new 30 hp on sale. 30 hp! We know many folks will think that is underpowering the whaler, but there are good reasons for just 30 horsepower. The leap from 30 to 40 horsepower means 158 pounds of weight increases to 232 pounds. 40 hp and higher must be installed by a dealer. We discussed it over lunch and decided that 30 hp will suit us just fine. It is new so we won’t inherit an old engine’s potential problems. Like I said, we are not speed freaks.

They used jumper cables from my car battery to test the electrical components on the engine.

It is only February, so there will be no “adding water” quite yet. Al is now working on sewing a cover for the whole boat.

And, of course, there will be a name for her.

Barbara Pawloski

WOW Very impressive. She looks great!!!

Taylor/ Jenkins

Outstanding….. you two are always so busy and your projects amazaing.

We think of you often from our nowwinter home in Sebastian, Fl since the hurricane took SeaHouse. Best of wishes to you. Deanna and Sarah

watsons

Ahhh Sara and Deana, you two are some of our favorite memories from our times in HopeTown. So good to hear from you!

M